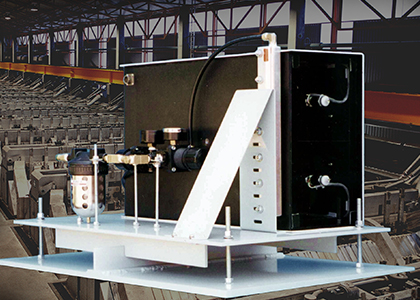

Aluminium Smelter Monitoring Systems

LOA-105 received method 14 approval to measure the roof vents of aluminum smelter pot rooms. The advantage is the sensors can be place in areas outside the hazardous HF gas.

- Spatially Averaged Measurement – The LOA-105 takes the average velocity rate over the entire optical path. Due to flow variations, this result provides a more representative measurement of the flow characteristics in a pot room unlike point-source sensors.

- Predictable Performance over Time – Designed for long-term use in a pot room, all critical components of the LOA are enclosed in air-purged housings and HF resistant windows are used to transmit the IR light into the pot room environment.

- Low Maintenance – Preventative maintenance is as simple as checking optical alignment and performing a calibration check using the TST-104. Since it is not directly exposed to the effluent, the LOA has better durability over instruments that are directly exposed to HF flow.

- The LOA-105 has received the seal of approval from the US government with EPA Method 14 Equivalency Approval (the rule for measuring airflow velocity in aluminum roof vents).